PVD Coating

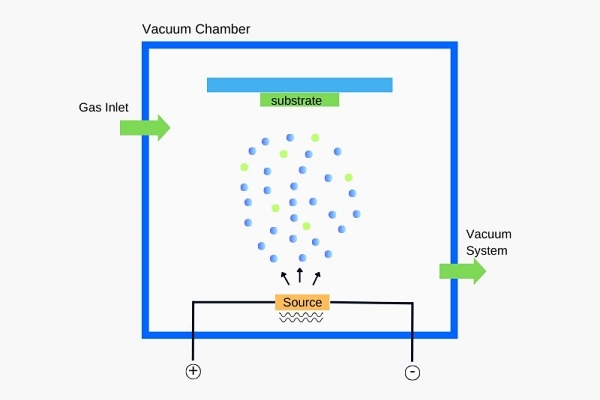

Itekhnoloji ye-PVD (i-Physical Vapor Deposition) ibhekisa kwitekhnoloji esebenzisa iindlela eziphathekayo phantsi kweemeko zevacuum ukufunxa imithombo yezinto eziphathekayo ibe yi-athomu yegesi okanye iiathomu, okanye i-ioni ngokuyinxenye ibe yi-ion, kwaye ifake ifilimu ebhityileyo enemisebenzi ethile ekhethekileyo kumphezulu we-substrate. .

Itekhnoloji ye-PVD yeyona teknoloji yonyango lomphezulu esetyenziswa ngokubanzi kuhlengahlengiso lomphezulu, ukusebenza, ukuhombisa, njl njl. yezixhobo kumashishini ahlukeneyo.

Ezona ndlela ziphambili zokubeka umphunga ngokwasemzimbeni ziquka:

›Ukufunxa umphunga

›Sputtering ukutyabeka

›Arc plasma ukutyabeka

›Ion ukutyabeka

SiyabonelelaUbushushu bobushushukwayeUkuphuphuma komqa we-electronizinto ezisetyenziswayo ezinxulumeneyo, kubandakanywa i-electron beam crucible liners, i-tungsten evaporation filaments, i-electron gun tungsten filaments, izikhephe, imathiriyeli yokuba ngumphunga, njl.

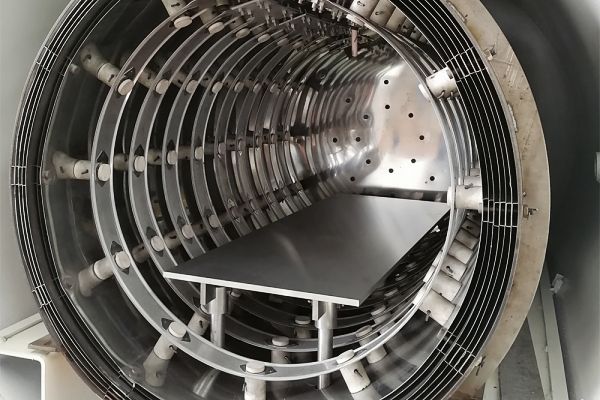

Vacuum Furnace

Iziko le-vacuum zisetyenziselwa ukudubula kwe-ceramic, ukunyibilika kwe-vacuum, indawo yokufunxa yombane yokukhupha igesi, i-annealing, iintsimbi zentsimbi, ukutywinwa kwe-ceramic-metal, ukubekwa komphunga womzimba (PVD), njl.

Sibonelela ngezinto zokufudumeza, izikebhe kunye nabathwali, izikhuselo zokushisa, iintambo ze-crucible, iingcingo ze-tungsten, kunye nemithombo yokufudumala, iindawo ezicutshungulwayo, i-fasteners, njl. Izinto eziphathekayo ziyi-tungsten, i-molybdenum, okanye i-tantalum, enokuthi yenziwe ngokwezifiso.

Ifotovoltaic kunye neSemiconductor

Isithando somlilo se-silicon enye yekristale, ekwabizwa ngokuba sisithando somlilo se-silicon crystal okanye i-silicon ingot furnace, sisixhobo esikhethekileyo esisetyenziswa kushishino lwe-photovoltaic kunye ne-semiconductor ukuvelisa i-ingots ye-silicon ekumgangatho ophezulu omnye.

I-silicon ye-Monocrystalline yeyona nto isisiseko sokwenza izixhobo ze-semiconductor ezifana neesekethe ezidibeneyo (ICs), iiseli zelanga, kunye nezinzwa.

"Indlela yeCzochralski" okwangoku iyona ndlela isetyenziswa kakhulu ekulungiseleleni i-silicon eyodwa-crystal.

Sibonelela ngeentonga zembewu ye-molybdenum, i-tungsten kunye ne-molybdenum crucible liners, i-fasteners, ii-hook ze-molybdenum, izando ze-tungsten carbide, njl.

Iglasi kunye noMhlaba onqabileyo

›Ishishini leglasi

Sibonelela ngee-electrode ze-molybdenum zokunyibilika kweglasi.

Ii-electrode zethu ze-molybdenum zenziwe nge-99.95% ye-high-purity molybdenum rods.

Ubungakanani be-electrode ye-Molybdenum: φ20-152 * L (iyunithi: mm), sinokubonelela nge-alkali ehlanjwe yi-alkali, indawo epholisiweyo ngomatshini, njl.

›Ishishini loMhlaba elinqabileyo

Ishishini lomhlaba elinqabileyo libandakanya ukutsalwa, ukusetyenzwa, kunye nokusetyenziswa kwezinto ezinqabileyo zomhlaba, eziyinxalenye ebalulekileyo yetekhnoloji ephezulu eyahlukeneyo kunye nokusetyenziswa.

Sinokubonelela nge-tungsten, i-molybdenum, kunye nezinto zokufudumeza i-tantalum, i-sintered tungsten, i-molybdenum crucibles, i-graphite crucibles, njl.

Izixhobo kunye nezixhobo zemitha

›I-Metal diaphragm: Isetyenziswa kakhulu kwiigeyiji zoxinzelelo lwe-diaphragm kunye nee-transmitters. Izinto esizivelisayo ziquka i-SS316L, i-tantalum, i-titanium, i-HC276, i-Monel400, kunye ne-Inconel625.

› I-electrode yomqondiso: Isetyenziswa kakhulu kwiimitha zokuhamba kwe-electromagnetic. Ubungakanani be-electrode yi-M3 ~ M8, kunye nezinto ezibandakanya i-SS316L, i-tantalum, i-titanium, kunye ne-HC276.

› I-electrode yomhlaba (iringi yomhlaba):Isetyenziswa ikakhulu kwi-electromagnetic flowmeters, edla ngokusetyenziswa ngababini. Ubungakanani buvela kwi-DN25 ukuya kwi-DN600, kunye nezixhobo ziquka i-SS316L, i-tantalum, i-titanium, kunye ne-HC276.

›Itywina le-diaphragm: isetyenziselwa ukwahlula isiqalelo somlinganiselo kumbindi. Izixhobo ze-diaphragm esizivelisayo ziquka i-SS316L, i-titanium, i-HC276, kunye ne-tantalum. ASME B 16.5, DIN EN 1092-1, kunye neminye imigangatho ekhoyo.

› Umsesane wokugungxula:esetyenziselwa ukutywinwa kwe-diaphragm edibeneyo ne-flange, enokususa intlenga kwi-diaphragm ngokugungxulwa kunye nokucoca.

› Ityhubhu yokukhusela iThermocouple:isetyenziselwa ukukhusela i-thermocouples yokusetyenziswa ngokuqhelekileyo kwizicelo ezahlukeneyo zoshishino. Sinikezela ngeetyhubhu ezikhuselayo kwezi zinto zilandelayo: i-tungsten, i-molybdenum, kunye ne-tantalum.

Nceda uqhagamshelane nathi okanye ujonge iwebhusayithi yethu ngeenkcukacha ezithe kratya kunye neemveliso.

Qhagamshelana nathi

Amanda│Umlawuli wentengiso

E-mail: amanda@winnersmetals.com

Umnxeba: +86 156 1977 8518 (WhatsApp/Wechat)

Ukuba ungathanda ukwazi iinkcukacha ezithe kratya kunye namaxabiso eemveliso zethu, ungalibazisi ukunxibelelana nomphathi wethu wentengiso (Amanda), uya kukuphendula ngokukhawuleza (ngokuqhelekileyo akukho ngaphezu kweeyure ezili-12), enkosi. .